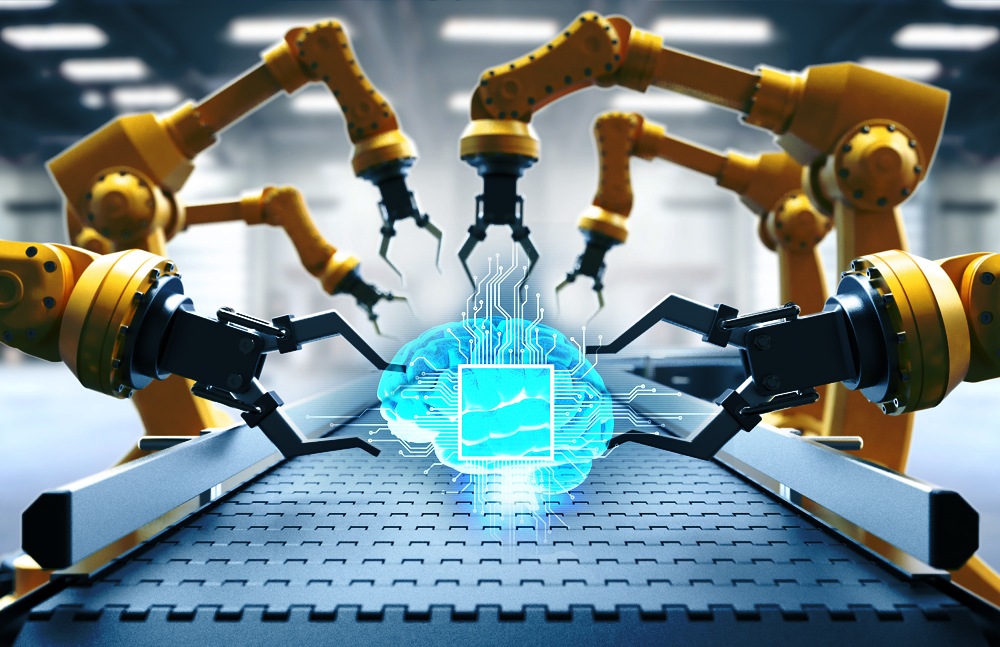

Artificial Intelligence (AI) has emerged as a transformative force in various industries, and manufacturing is no exception. With its ability to analyze vast amounts of data, identify patterns, and make real-time decisions, AI is revolutionizing manufacturing processes, enhancing efficiency, productivity, and quality. In this article, we’ll explore how AI is optimizing manufacturing processes and reshaping the future of industry.

Predictive Maintenance:

One of the significant applications of AI in manufacturing is predictive maintenance. By leveraging AI algorithms to analyze equipment sensor data, historical maintenance records, and environmental factors, manufacturers can predict when machinery is likely to fail and proactively schedule maintenance before breakdowns occur. This approach minimizes downtime, reduces maintenance costs, and prolongs the lifespan of equipment, ultimately improving overall operational efficiency.

Quality Control and Defect Detection:

AI-powered vision systems are revolutionizing quality control processes in manufacturing. These systems use computer vision algorithms to inspect products for defects, deviations, or irregularities during the production process. By detecting defects in real-time, manufacturers can address issues promptly, minimize waste, and ensure that only high-quality products reach the market. This not only enhances customer satisfaction but also reduces rework costs and improves overall product consistency.

Supply Chain Optimization:

AI algorithms are also optimizing supply chain management in manufacturing. By analyzing historical data, market trends, and external factors such as weather or geopolitical events, AI can forecast demand, optimize inventory levels, and streamline logistics operations. This enables manufacturers to reduce lead times, minimize stockouts, and lower transportation costs, ultimately improving supply chain efficiency and responsiveness.

Process Optimization and Resource Allocation:

AI algorithms can analyze manufacturing data to identify inefficiencies in production processes and optimize resource allocation. By analyzing factors such as machine utilization, energy consumption, and workflow bottlenecks, AI can suggest adjustments to improve production efficiency, reduce waste, and minimize costs. This data-driven approach enables manufacturers to optimize resource utilization, maximize throughput, and enhance overall operational performance.

Human-Robot Collaboration:

AI-powered robotics are transforming manufacturing operations by enabling seamless collaboration between humans and robots. Advanced AI algorithms enable robots to perform complex tasks with precision and flexibility, while also enhancing safety and ergonomics in the workplace. By automating repetitive or dangerous tasks, AI-driven robotics free up human workers to focus on higher-value activities, such as problem-solving, creativity, and innovation, thereby increasing overall productivity and job satisfaction.

Challenges and Considerations:

While AI offers immense potential for optimizing manufacturing processes, its implementation is not without challenges. Data privacy and security concerns, the need for specialized talent, and the risk of job displacement are among the key considerations for manufacturers adopting AI technologies. Additionally, ensuring interoperability and compatibility with existing systems and processes can be a significant hurdle.

In conclusion, AI is revolutionizing manufacturing processes, driving efficiency, productivity, and innovation across the industry. From predictive maintenance and quality control to supply chain optimization and human-robot collaboration, AI-powered solutions are reshaping the future of manufacturing. While challenges remain, the potential benefits of AI in optimizing manufacturing processes are undeniable, and forward-thinking manufacturers are embracing AI technologies to stay competitive in an increasingly digital world. As AI continues to evolve, its impact on manufacturing is poised to grow, unlocking new opportunities for efficiency, sustainability, and growth.

Equipo T2S1.